[Queue the theme song]

The Good, I started on the rear brakes last night.

The Bad, I can’t finish the project.

The Ugly, I found a broken axle half shaft.

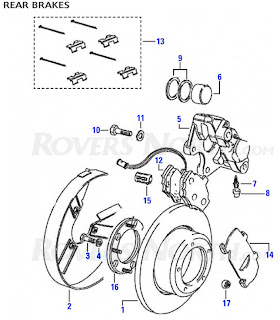

As you can see in this picture the rear brakes on the Range Rover are looking pretty knackered. I love that word “knackered”. In this context I’m using the British and Irish slang form. But it works as well for me on the British/Australasian level too. For when I saw the broken half shaft I translated it into American English and that was one of the words I used do describe my disappointment. RovErica, while driving her UN-air conditioned Taurus, is famous for her saying, “Dad it is hot as balls in my car.” It was definitely “hot as balls” in the garage while I was working on this project. The temperature was still above 95F when the sun started going down. Considering all this, knackered works on many levels.

|

I bought a full set of discs and decided, like all the new items I put on the Rover, to limit the rust the best I can. I decided that a coat of acid etching primer would be just the thing. You might ask, “Will it work?” Who knows, but I feel better about them being painted.

So I took the new brake discs and painted them with the primer. It was not my intention to paint the actual braking surface but through my laziness efforts and impatience some healthy overspray, I got paint on the braking surface. I don’t think it matters for when the brake pads start making contact there won’t be much paint there after a few stops.

After I had put the first coat of paint on the discs I noticed an irregularity on one of the front discs.

After checking with several sources (JagGuy and The Evil German Dude) it was determined this was done to balance that disc. I had seen this before, but wanted to make sure.

Swapping the discs is a pretty straight forward job. You remove the caliper, or as EGD says the “ka-LIPer” (I wish I had an audio file of him saying that for you). This requires the brake lines on the rear brakes to be removed. So have a catch pan available or you will have a huge mess. The brake lines are “hard piped” as in not flexible at the caliper. The flexible part of the brake line on the rear axle is in the center above the axle.

After you have the caliper off, it is time to remove the axle half shaft. That can be seen in this picture.

Five bolts and you are done.

Pro Tip: I used a breaker bar to hold the wheel in place as I broke the bolts lose. I also had to use a cheater pipe to extend the leverage of the socket and ratchet. I’m getting wimpier in my advanced age.

I used a large screw driver to slip between the axle half shaft cap and the hub. Once you break the seal it comes out easily. You then flatten out the keeper ring and remove the bearing nuts. These nuts are very large and I used the biggest channel locking pliers to get them started. They were not very tight in the first place but the grease made them very hard to work with.

Here is another “good” for this project. It is a good idea to replace stuff as you go through the vehicle you are working on. In this example the wheel bearings are in these hubs. I remember I had bought a wheel bearing replacement kit some time ago when RovErica reported some odd behavior and noise. From what she described I thought the bearings were going out. It turned out not to be the case and I had the kits still sitting on the shelf. My axles have 185,000 miles on them. So basically if you break something down this far, go ahead and replace the serviceable parts while your there, if your budget can afford it. I will store the old bearings “for good measure” as I believe they were not bad in the first place and will work in a pinch if necessary.

After you have the hub off it is time to remove the disc from the rest of the hub. This is done by removing the crown nuts that hold the anti-lock brake sensor ring.

And those thread shafts pass through the disc holding the hub to the disc. They are dual threaded. Both ends are threaded and this may cause you trouble when you attempt to take the crown nuts off. Be creative. Extra points are awarded to you for removing the ring if you have to deploy additional tools or techniques. Rovers North has a good picture of the ring and assembly and how it all fits together. Click on the picture to open their site for a complete parts list.

With a little persuasion gentle tap of a hammer the hub and the disc will separate. Reassemble in reverse order. If you have a bearing kit to install you will need to do that as well. If no, definitely renew the grease on the old bearings. I will post another entry when I put the new bearings back in.

Right now I’m debating if I’m going to bother sand blasting and painting the hub unit. I really want it all to be pretty and new so maybe perhaps.

Now on to the broken axle half shaft.

This crappy photo shows the sheared off end of my right rear axle shaft. After seeing this and an expletive laden rant a little disappointed cursing, it hit me, I will have to tear the differential apart. KNACKERS!

If we refer to the rule above, now would be a good time to put in a locking differential. But sadly the budget does not support it. What? You’ve never had the axles out of your Rover? Click here to see what a proper shaft should look like. In short, it depends on who you ask and what you are doing with your Rover.

IF we, that is you and I, were sitting in my garage having a Bodington’s the conversation might turn to 10 spline versus 24 spline axles at this point. Basically in mid-1993 Land Rover started using 24 spline axles instead of 10 spline. Are 24’s better than 10’s? There is a thread on RangeRovers.net in their forum. Check it out for wisdom on the subject.

So another phase of the project will be to assess the damage done and get the axle half shaft piece (or pieces) out of the differential. Gag.

As I posted in an earlier post, everything I touch generates two (2) more projects. At this pace I may never finish the restoration. I am trying to keep a positive outlook on everything, but Mrs. OkieRover is wondering how much this will all cost and when will it be done. As I told her, this is my “mid-life crisis motorcycle”.

I am respecting her wishes that I not buy a motorcycle. I’m hoping she realizes that this is my hobby and in her mind, is a lot safer than a motorcycle. Well, it’s a lot safer than ME BEING ON A MOTORCYCLE.

Thanks for reading and Happy Rovering.