The last of summer has finally left the building. Here in Oklahoma that means the temperatures drop, from 100s to 80s and it means allergies. Pollen this time of year consists of the big three: grass, ragweed, chenopods. It is hard on all those affected. The pollen count numbers we saw were ridiculous. On a twelve point scale, we had weeks where the number stayed in the eleven range. At one point, we had three 11.8 days in a row. I spend that weekend, inside as much as I could. As you can imagine this year was very hard on me. I did avoid getting pneumonia this year from the pending lung infections, so I had that going for me.

One of my dogs, Sophia, is allergic to grass. This time of year, she is a scratching insane ball of irritated canine. She is grumpy and needy of our attentions at the same time. She has finally turned the corner and will soon be scratching less. I too have turned the corner and was able to return to the garage to continue the death march of restoration.

I call it a death march because it seems like it will never end. You can imagine trudging on and on, day after day, with no end in sight. This Range Rover is trying my patience for sure. As I mentioned in other posts, every thing I touch produces two new projects. With that type of progress you can almost see yourself walking backward toward your goal.

I have finally finished the installation of the brake rotors. I have repacked the bearings all the way around which is on a tick chart somewhere of maintenance NO ONE likes to do. When I fill the brake system with fresh fluid it will also allow us to check off another item on a “Not fun” tick chart somewhere.

I took the failed Craftsman tools back to my local Sears store for replacement. I had damaged or broken a screw driver, a punch, and a 1/2 inch 14mm twelve point socket. The socket as you may remember had traveled half way around the world with us to Guam and back. After the clerk had handed me the tools, I mentioned that fact to her. I told her the socket was at least 40 years old and had been half way around the world, twice. I also told her that as far as antique tools goes this one qualified and there was someone out there that collected them. As I left the store she was eyeing the socket with a little more interest.

Over the years I have noticed the brake reservoir has some minor cracking on it. It resembles how a porcelain plate cracks. I knew there would be a day in the future when that broke and left me in a lurch. I bought a replacement reservoir and endeavored to replace it.

You can see the cracking in this picture. What I learned from this exercise is the reservoir is a lot sturdier than I believed it to be. The old reservoir would probably have lasted the life of the Range Rover. Instead I have a spare on the shelf now in the form of my old tank.

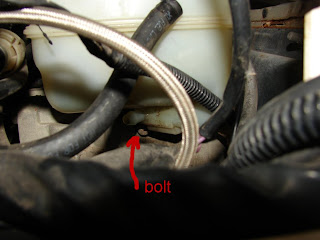

The removal is pretty easy. There is a single bolt holding the tank in place. The hardest part was getting the correct tools to remove the bolt. The head is a hex size 5. I put an extension on the end of a 1/4 inch socket and the hex head bit size 5 on the end of that. You have to remove a low pressure hose from the bottom held in place by a hose clamp. Most hose clamps in America have a 1/4 inch socket head on the drive nut. I have run into clamps with larger heads. Diet Mountain Drew’s friend SeaDawg’s BMW 325is has a hose clamp that was larger, but this one was a 1/4 incher.

I managed to get it under there and on the bolt. It came out with not too much effort.

I had not at this point learned that my new tank came with a replacement so I put the rusted screw on the wire wheel to clean the rust off. I installed the new reservoir and went to put the old reservoir in the box and up on the shelf when I learned there was a new screw and a new set of rubber seals for the new tank to rest in. So I got to install the tank twice.

The install is pretty easy. Remove the old tank. I used a large screwdriver as a lever to lift the tank as I pulled up. I popped out the old rubber seats and replaced them with the new ones. Now, having done this twice I can tell you the secret to an easier time getting the bolt back in. The part I bought had a metal bracket held in place by a channel molded into the bottom of the tank. The metal bracket moves freely. Slide it out a bit and check the alignment BEFORE you push the new tank into the seals.

Before you put the tank back in place connect the low pressure brake fluid hose. You can see it much better in your hand than buried behind all the hoses and wires. Line the tank up and gently press the tank into the new seals. Reconnected the low pressure brake fluid hose and screw it all down with the new bolt.

This is a really crappy picture of the old rusted hose clamp. It was so badly rusted the drive nut was basically welded in place. I replaced it with a new clamp.

It is easier to replace all this if you remove the ABS pump and the vacuum accumulator and the coil. This fender is full of stuff. And from looking at this picture of swiss cheese the top of the fender, things have been moved around a bit. And those relocations required new holes be drilled.

I’m the kinda guy who uses the existing holes when ever possible. I know I drilled a few of these holes. But no where near all of them. And as you may guess…that’s right it was badly rusted. Big surprise, NOT!

The more I encounter the rust on this Rover the more I’m guessing its days are numbered. If I had the money, a donor Rover and the time, a frame off restoration would be required. I have just resolved I will just protect the metal I can and see what happens in the future. I got the angle grinder out and knocked off all the rust I could and covered it with acid etching primer and Rust-oleum automotive primer. I covered the top and the bottom of the fender with several coats of paint.

In the process of removing all the parts from the fender I found the broken rubber mounts for the ABS pump. The good news was I only needed to cut two of the four off because they were so badly rusted wrenching them off was impossible. It seemed like every bolt and nut on this fender was badly rusted. Several of them broke instead of coming apart traditionally.

I will have to get an assortment of stainless steel bolts and nuts to put everything back together. I’m debating on designing my own ABS pump mounts. I think I could do something with a set of rubber stoppers cut down and drilled with some stainless bolts. I’m pretty sure it will work as well as the factory designed ones.

These mounts are available from several suppliers. Atlantic British has them listed at 7.95$(US) each. The stoppers, stainless bolts, washers, and nuts will probably be about the same cost, WITH NO RUST. I’ll post up my results when I decide.

I also don’t like the GIANT gap in the fender near the shock tower. I’m going to be looking into some rubber sheets to cover these spaces. This is the awkward segue to discuss the mud flaps.

To be have mud flaps, or not to be to have mud flaps: that is the question:

Whether ’tis nobler in the mind to suffer the slings and arrows of outrageous fortune have ground clearance, or to take arms against a sea of troubles not have as much ground clearance, blah, blah, etc…

William Shakespeare – Hamlet

Few people know that Bill was a huge fan of “green laning” and wrote those prophetic words while sitting in a carriage that was hung up on its mud flaps in a field near Guildford. He changed the words slightly to highlight Hamlet’s dilemma over life and its many torments.

I have long ago lost the mud flaps. The brackets for the flaps are attached in the front to the wheel well and provide three more holes for water to get under the carpet. Great idea guys, have another Guinness or twelve on me. I can only guess these holes did not contribute to the water in the floors but it’s anyone’s guess.

I have painted the brackets and cut off the rivets that held the old flaps. I have stainless steel hardware ready to attach new mud flaps. The question now is…do I want mud flaps?

I read a debate about this on a forum many years ago. I have removed my running boards and the mud flaps failed and fell off or were ripped off long ago. The debate was basically that of “ground clearance”. I’m not a fan of mudding. I know there will be places I go that will be muddy. But I can tell you I’m pretty sure I will NOT be driving the Range Rover into mud pits, AKA mud bogging.

The question of cost is also hanging over us. A mud flap costs about 10$(US) for my Range Rover at Atlantic British. All of the suppliers are about the same on the cost. At that cost there isn’t much point in finding a source for a sheet of rubber that might reduce the cost. So for around 40$(US) plus shipping I can put mud flaps back on my Range Rover.

Finally, well for this post anyway, I sprayed some of the rubberized coating material. I sprayed the floor on the driver’s side where the holes for the mud flaps are located. I sprayed the bottom of the footwell too. I got the angle grinder under there and cleaned the holes of any rust.

I will install the stainless steel hardware and then spray the spots again for good measure. I think any holes I can get too will get a stainless steel bolt and nut with washers to close the hole. I can then spray those with the rubberized spray inside and outside.

I was warned about using this product. Mainly if you cover up rust with it, the rust will eat the metal under the coating and you will never know it. I have used it only where I think there is no longer any rust.

I also coated the rain gutter at the tailgate end of the back. As you recall this is where I found the first rust on this restoration project. I have at least three coats of paint on the metal here. I figured any water I can encourage to go out of the Rover on a nice rubberized gutter the better. As a disclaimer I will state at this time, “I have no fantasy what-so-ever that this product will help me with the rust problems on this Range Rover.”

I mostly disavow any hopes here because from what I’ve seen this Land Rover’s days are numbered. How many you might ask? I have no idea. Hopefully it’s a decade or more.

So it’s off to the hardware store Lowe’s to buy stainless steel hardware. And once everything is bolted back down, bleed the brake system. And then the project I’ve dreaded most, the viscous coupling, will begin.

Wish me luck…as I post this the allergies are acting up and I’m packing a snot rag every where I go.

Thanks for reading and Happy Rovering.